Delivering the clean you can count on!

Now serving the Greater Phoenix area

With a keen eye for detail mixed with a little OCD, a touch of autism, and relentless passion for service means we continuously invest in improving our processes to ultimately deliver a level of clean that you'll tell all your friends about.

Alpine is a leading provider of dry ice blasting services across several industries throughout the Phoenix metropolitan area.

Mike Martin

Alpine Dry Ice Blasting Founder

Restoration plans that meet your needs

Industries We Serve

All you need to know

Frequently Asked Questions

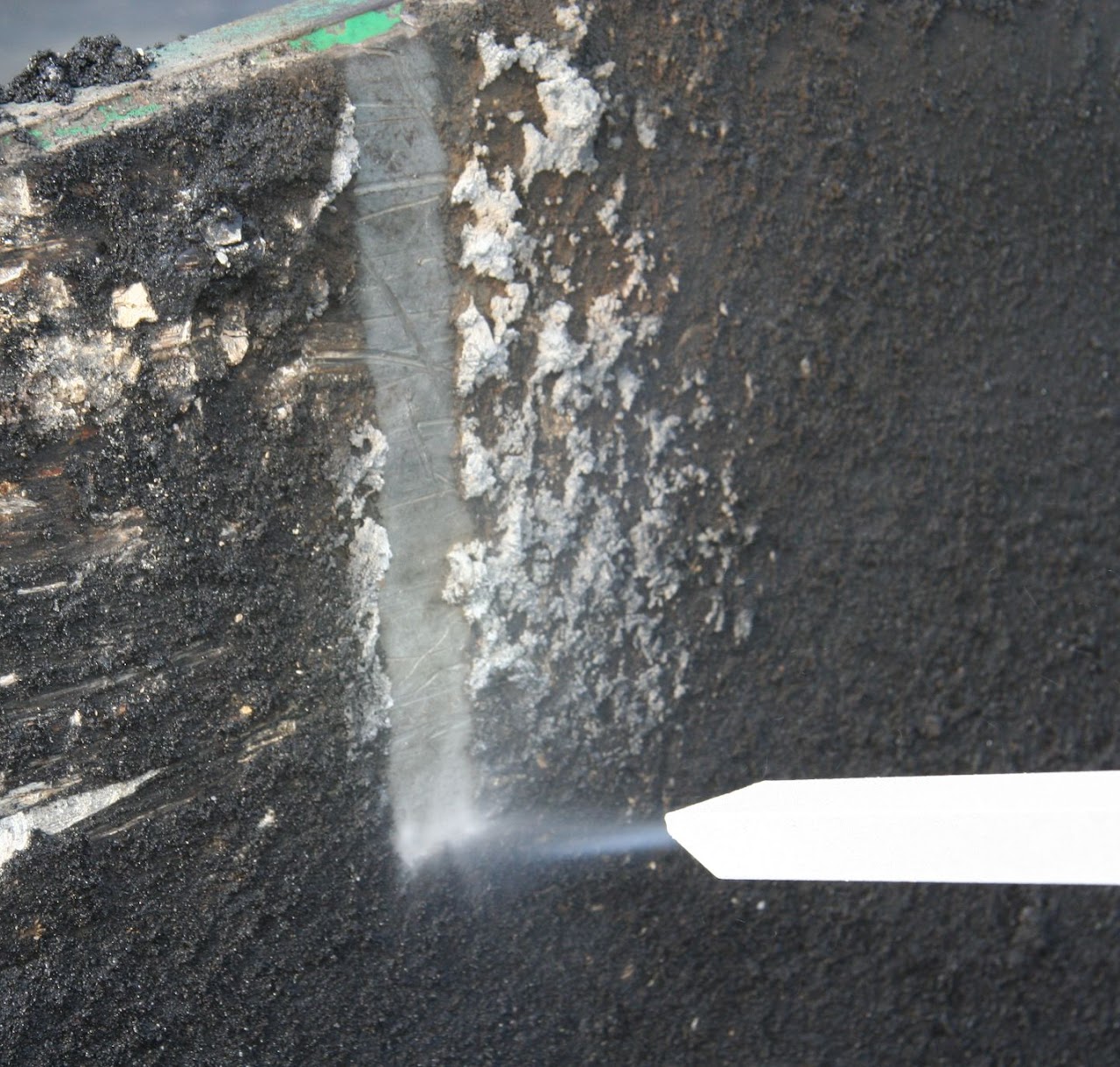

The initial kinetic effect is caused by a high speed collision between the dry ice particles and the cleaning surface. Because of the properties of solid carbon dioxide, it instantaneously evaporates upon impact.

As a result of the below freezing temperatures, a thermal shear effect is created. This effect happens from the extreme and sudden temperature change on the surface of the cleaning area. It then causes the contaminants to become brittle and break its bond from the surface.

Finally, the dry ice pellets sublimate and cause a rapid expansion upon impact. This effect efficiently removes the contaminant without any secondary waste or residue.

Custom Plans For A Clean, Healthy, and Beautiful Environment. Submit contact form below for a free estimate

Restoration plans that meet your needs

Industries We Serve

Our dry ice blasting cleaning service is safe for use in food production and packaging facilities, as it uses no chemicals or water. It is effective in removing bacteria, mold, and other contaminants from food processing equipment and packaging machines, ensuring that your facility is clean and safe for food production.

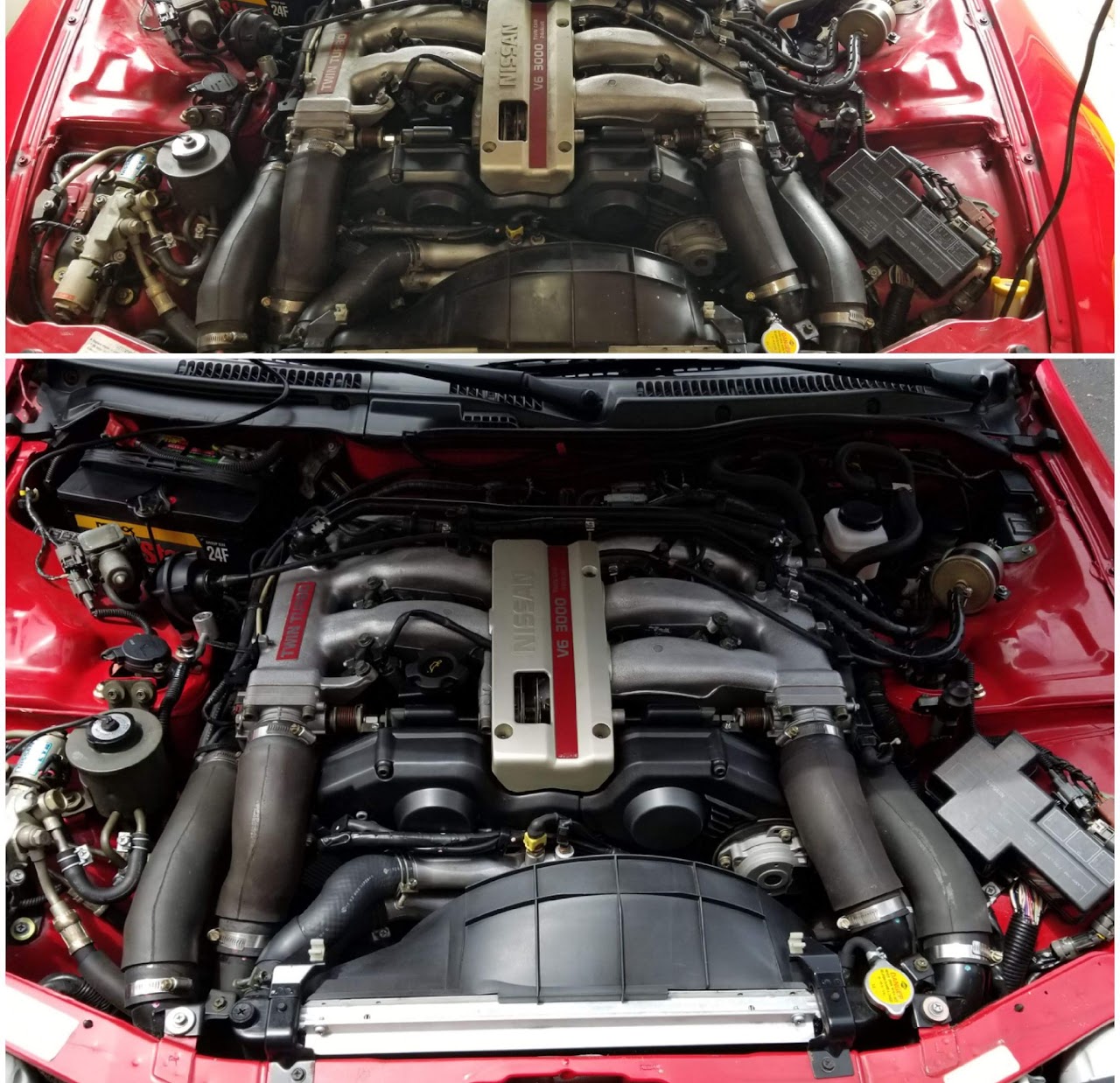

Our dry ice blasting service is ideal for automotive cleaning, as it can remove PPF, grease, and other contaminants from cars, chassis, and other components. It is also safe for sensitive electronic equipment, ensuring that no damage is done during the cleaning process.

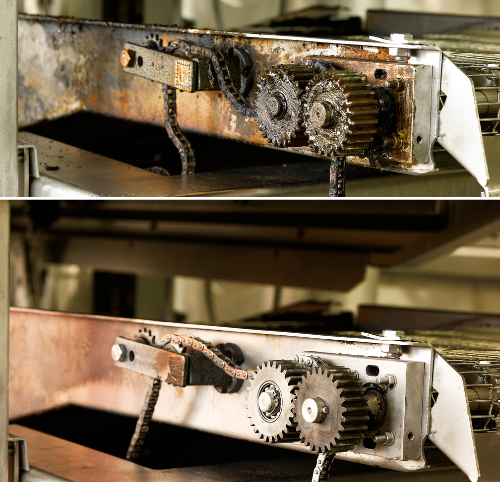

Dry ice blasting is perfect for cleaning molding and assembly line equipment, removing residue, oils, and other contaminants that can cause equipment failure or production defects. Our cleaning process is fast, efficient, and cost-effective, allowing you to keep your production line running smoothly and reduce downtime. Using this service can cut downtime to less than half of the time compared to traditional cleaning methods since there is no “dry out time”.

Our dry ice blasting cleaning service is ideal for the aerospace industry, as it can effectively remove loose paint, grease, and other contaminants from aircraft engines, fuselages, and landing gears. It is also safe for sensitive electronic equipment, ensuring that no damage is done during the cleaning process.

Our dry ice blasting cleaning service is ideal for cleaning electrical power generation equipment, including turbines and generators. It can effectively remove contaminants, such as oil and grease, that can cause equipment failure, and it is safe for sensitive electrical components.

Our dry ice blasting cleaning service is highly effective for removing light rust, lubricants, shaving deposits, and other contaminants from metal fabrication equipment such as presses, rollers, and lathes. This ensures that your equipment performs at its best, reducing the need for repairs and increasing your production output.

Our Pricing And Plans

Please explain your needs in the contact form below and we will provide a same-day quote.

get in touch

We take great pride in everything we do and hope you will pay us the ultimate compliment -

"you guys definitely have OCD."